The History of Danish Pipes

by Jakob Groth (DK) - adapted and

illustrated by Jörg Lehmann

With kind permission

JAKOB GROTH leave us in August 2007 after a long enduring illness in his early 40ies. We will nerver forget his effort on pipes and pipe-related topics.

Introduction

This is a short history of Danish hand made pipemaking leading to a presentation of many of the Scandinavian pipemakers after WWII. The purpose is to give a general view of the environment in which this special handicraft art has developed, and to present the main people involved. This presentation does not pretend to be complete, so useful comments are encouraged and will be received with thanks.

Since we will concentrate on pipemakers, let us start with a definition. For our purpose, we will define a pipemaker as an artisan who makes pipes from start to finish. The pipe is the creation of one person; he takes care of the whole process himself. Furthermore, an artisan pipemaker shapes his pipes by hand. A pipe factory shapes its pipes from a master pipe as a template and produces a series of exactly the same pipes. A pipemaker's pipe is individual and no two pipes are identical. The first part of the pipemaker definition excludes some of the pipe producers, like Nording for example, since they have several employees and division of labour for the various stages of pipemaking. We will call a pipe made like this a semi-hand cut pipe.

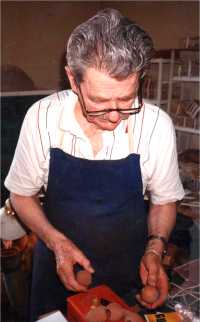

There is general agreement upon the fact that the story of Danish pipemaking begins with a Swede: Sixten Ivarsson. During the second World War Sixten Ivarsson lived in Copenhagen and worked as a debt collector. When he broke the stem on his pipe he went to a workshop - Suhrs Pibemageri (Suhr's Pipe Work Shop in Copenhagen) - to get his pipe repaired. Unfortunately the repairman was out sick for a period, so Sixten had to fix it himself. He did this so well, that he was offered immediate employment. During the war it was practically impossible to buy new pipes, so Sixten was very busy with the repair job. From this Sixten learned a lot about how pipes should be made and perhaps more important - how they should not be made.

After the War it was again possible to import briar and Sixten began to experiment with making his own pipes along with the repair job. Since at this time it was still not possible to get the desirebel English briar pipes again, Sixten was able to sell his pipes even though they were 5 to 10 times more expensive than the Danish factory pipes (which at that time were not of good quality).

In the 50's Sixten developed his pipe shapes. From the traditional English shapes, starting with the Billard, he made a number of variations that were later to become classics. At the same time he started to collaborate with Stanwell. This also led Sixten to go into business for himself. Sixten had a disagreement with the owner of Suhrs Pibemageri about royalties for the shapes he created for Stanwell. Stanwell was the only Danish pipe factory started during the War that survived the later reentry of English pipes into Denmark. We shall return to Stanwell, even though it produces factory made pipes. Sixten was never been afraid to teach others, so many of Stanwell's modern shapes from the 50's and 60's are creations of Sixten Ivarsson. In this way Danish Design was spread worldwide by Stanwell just like it was spread with the popularity of modern Danish furniture.

In

the 60's Danish pipes had their breakthrough. There was an enormous growth in

the export both of factory and pipemaker pipes. This enabled many new pipemakers

and workshops to start up in Denmark. Several workshops even became schools for

different directions among pipemakers, many of them still famous. Even today, it

is often possible to see these characteristic features in the pipes made by

pipemakers who were educated in one of the following

important workshops:

Sixten

Ivarsson, W.O.Larsen

and Poul

Rasmussen

Sixten Ivarsson as a teacher

Sixten Ivarsson as a teacher

Besides

being the first great createur, Sixten was also a very good teacher. One of

Sixten's mottoes was " It is a bad teacher that does not allow his student

to become better than himself." Some pipemakers have directly had the

pleasure to be taught by Sixten while many have had indirect inspiration.

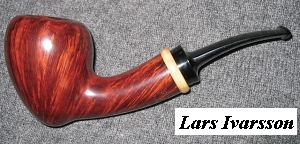

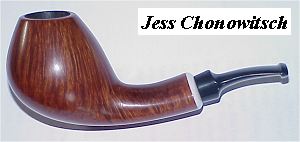

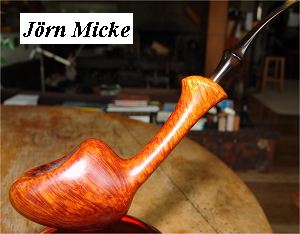

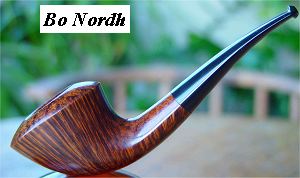

Pipemakers who were taught or guided by Sixten include prominent names like: his

son Lars

Ivarsson, Jorn Micke,

Jess

Chonowitsch and

Bo Nordh.

(The

indicates an exdented

summary about the particular pipe maker in English - Check it !)

Typical for the Sixten School is that he always emphasized very good quality in the workmanship. All details must be done with a high degree of perfection. It was very important to Sixten that the pipes were good smoking instruments - even though the shaping of the pipes is more sculptural than in the other schools. Many of these pipes can be seen as the work of a sculptor trying to make the most of the briar as an interesting material. This means that many of the pipe shapes are asymmetric, in soft and flowing shapes. Often the finish of the pipes is in a various shade of brown. We realize that when we are talking about characteristics, you have to see dozens of pipes from different pipemakers from a School before you can see a common thread. At the same time, some of these pipes may not have the characteristics of the School.

Any copying, publication or reproduction of the papers and / or pictures published herein in printed or electronic media is strictly prohibited without the explicit written consent of these pages' owner. (c) Pipendoge, 2009